Our Low Carbon strategy

Reduce our environnemental impact

The company aims to rise to the challenges of climate change. It is both a moral obligation and an entrepreneurial challenge.

This is why the Group is committed to reducing the environmental impact of its activities.

Improve the environmental impact of our offers

Reduce our internal environmental impact

Change management process

The implementation of this Group-wide commitment requires a genuine change management process to be instilled at all levels of the company, in terms of processes, skills, and best practices.

Since 2021, a team of experts, the Low-Carbon Division, has been developing and leading the Group’s Low-Carbon approach.

Its objective : to be a driving force in reducing and managing carbon impact, while actively developing new levers of the circular economy.

Mastering environmental expertise to build responsibly

The role of the Low-Carbon Division is to:

- Deploy the Group’s environmental and CSR ambitions

- Be a trusted carbon partner for our project owners

- Anticipate regulatory changes and emerging challenges, and support the transition in skills and professions

- Support all of the Group’s business units

The topics addressed reflect the scale of the environmental challenges we must fully embrace: carbon, circular economy, energy, biodiversity, construction site nuisances, and more.

The 4 levers for Low-Carbon deployment at Léon Grosse

1. Training and Awareness

2. Project Support

3. Tools and Solutions

4.Technical and Regulatory Monitoring

1. Training and Awareness

Developing Internal Skills

While building on existing initiatives and experiences, the Low-Carbon Division shares its expertise with our operational teams through dedicated training programs, shared documentation, and internal communication.

The goal? To ensure that every project integrates best practices in carbon neutrality.

- Training & Knowledge Sharing: A dedicated Low-Carbon section on the Intranet, regular newsletters, and open-access MOOCs on topics such as the general French framework, SNBC, RE2020, and carbon calculation.

- Circular Economy & Reuse: Targeted training to promote more sustainable and responsible approaches on our construction sites.

Raising Awareness Among External Stakeholders

We actively engage in dialogue with our partners to share best practices and foster increasingly sustainable projects. From the earliest stages, we exchange and align our vision with project owners, architects, design offices, and partners.

2. Project Support

Technical Support from the Study & Design Phase

The Low-Carbon Division provides expertise to operational teams during both the tendering and project design phases. Its support covers both technical and contractual aspects to ensure the best alignment between environmental ambition and project feasibility.

Rigorous Monitoring During the Construction Phase

During project execution, the Low-Carbon Division ensures that the environmental commitments defined upstream are met:

- Compliance with targeted labels and certifications

- Reuse and circular economy objectives

- Reduction of the project's carbon footprint

3. Tools and Solutions

◎ Accurate Measurement with the Carbon Calculator

To meet the project’s carbon threshold, we conduct rigorous tracking of its carbon footprint from design to delivery.

The Nooco calculator enables teams to easily integrate environmental considerations as early as the design phase.

Thanks to the interconnection between our cost estimation software and Nooco, calculating the carbon footprint of each operation becomes more streamlined.

During execution, we continuously adjust our low-carbon actions to stay aligned with the defined carbon objectives.

◎ A Low-Carbon Solutions Catalog for Effective Action

We have developed a dedicated catalog, accessible to all operational teams, which includes:

- Innovative low-carbon construction solutions to optimize the overall environmental impact of buildings

- A selection of recycled materials that reduce project carbon footprint

- Circular economy solutions and services that promote reuse and waste reduction

Partnerships

Surrounding Ourselves with Trusted Partners

- Partnership with Vicat: Our goal is to jointly position ourselves on low-carbon projects and develop collaborative R&D initiatives (specific low-carbon concretes, new industrialization processes, prefabrication, 3D printing, etc.)

- First General Contractor to Join the Reuse Booster: Led by A4MT, this initiative aims to structure and strengthen demand for material reuse

- Collaboration with Reuse Companies: The objective is to give materials removed from our sites a second life. When possible, we also seek reused substitutes to replace new materials such as interior joinery, sanitary equipment, raised floors, and fittings.

4.Technical and Regulatory Monitoring

Regulatory Monitoring and Label Tracking

We closely monitor regulatory and normative developments (RE2020, REP, PEMCB, etc.) to ensure that the Group anticipates and integrates these requirements into its practices.

Technical and Commercial Watch

We analyze new trends and external pilot initiatives to identify best practices and incorporate them into our projects. This commitment includes:

- Participating in forums and trade shows to capture innovations in the sector

- A partnership with Impulse Partner, enabling the organization of internal pitch sessions dedicated to start-ups and innovative products

Our low-carbon solutions developed internally

Panobloc® by Techniwood

Prefabricated wood facades

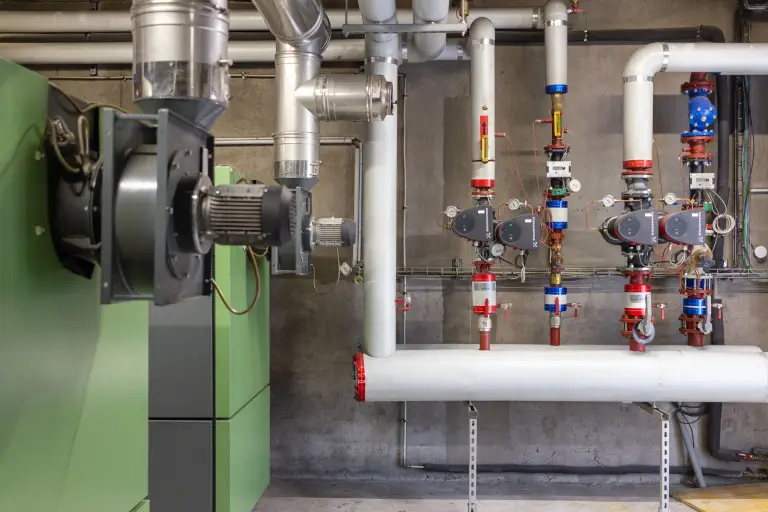

Biomass heating by Voé

Integrated heating to the building or in exterior

Wood pellets by Granuloé

Pellets produced locally from wood residues

Evost by Kyotec

The complete heating, ventilation and air conditionning system

Our low-carbon operations

Le 8e Chemin - Construction d'un ensemble mixte

Construction en gros-oeuvre seul :

- d’un secteur résidentiel répartis sur 6 bâtiments : 100 logements dont 20 logements sociaux en R+2 + VETC

- réalisation d’une placette à l’entrée du site avec 2 commerces de services au RdC des bâtiments

- sous-sol à usage de stationnement de 100 places

Construction en Entreprise Générale :

- d’un secteur tertiaire comprenant 4 bâtiments en R+1 et attique avec un niveau de sous-sol à usage de stationnement de 80 places

- d'un parking extérieur de 50 places

- réalisation d’une voirie centrale, dédiée aux piétons et modes doux, qui traverse le site d’ouest en est.